Abstract

In this work we studied the reactivity of the Trifluoroacetic acid hydroxylamine system in the one step salt free synthesis of amides from ketones. A particular regards was paid to the caprolactam synthesis because of its industrial relevance. Synthesis, reactivity and characterization of the hydroxylamine trifluoroacetate is given. Fast oximation reaction of several ketones was gained at room temperature (1 h of reaction quantitative conversion for several ketones). In the same reactor, by raising the temperature at 383 K, the Beckmann rearrangement of the so obtained oximes is easily accomplished in the presence of three equivalent of TFA. The possibility of obtaining the trifluoroacetate of the hydroxylamine with a modified nitric acid hydrogenation reactions was verified, too. Reuse of solvent and trifluoroacetic acid is easily achieved by distillation.

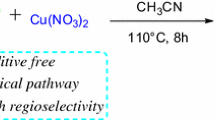

Graphical abstract

Salt free one-pot caprolactam and amides process catalyzed by CF3COOH, in the presence of NH2OH TFA as the oximation agent.

Similar content being viewed by others

1 Introduction

Caprolactam is a chemical whose importance raises continuously from the beginning of its industrial production being the monomer of the important polyamide nylon 6. Despite of the large number of studies a definitive waste free a process is not available until now [1]. Problems of coproduction of side products of low economic value affects current industrial processes, or in additions, for certain cases these coproduction are real waste, whose disposal decreases the sustainability of the whole process [2]. Recently, salt free processes are running in the Far East by employing a step of cyclohexanone amoximation and a second step of Beckmann rearrangement in gas phase [1]. The Eni amoximation step and the Sumitomo gas phase rearrangement are the core of this salt free processes. More recently, Sinopec has claimed similar route employing both an amoximation step and a gas phase rearrangement [3]. In both cases, however, a complete transformation of the traditional plants, based on liquid phase reactions, needs for running this type of process. In fact, the revamping of existing plant in Europe and USA could be a more economically and environmentally sustainable way, since the demand caprolactam in the western regions does not growth as in the Far East [1, 4,5,6]. Starting from such an idea, of having small plant modification for caprolactam process, a need of integrated one pot liquid phase reactions are of interest from both economics and environmental point of view. For this reason the research in this field is in continuous development and only in the last two years has appeared several papers and, in addition, two comprehensive review on the argument [7, 8]. The oximation step occurs generally in high selectivity but in the presence of a stoichiometric amount of a base, which leads to the formation of the salt deriving from neutralization of the acid of the hydroxylammonium salt, is the main concern of this step. Actually, this byproducts is one of the main issue of the whole process [1, 2]. Recently, literature have reported new methodologies giving good yields in ketones oximation carried out in ionic liquids, so that avoiding the neutralization [9]. Besides organocatalysts improves such a step by increasing the yield in the oximes formation, particularly useful for ketones with low reactivity, especially for those with steric hindrance at the carbonyl. [10].

Recently, the chemistry of trifluoroacetic acid as organocatalyst has been suggested for the synthesis of the caprolactam, of other amides as well as to several other reactions of industrial interest [7,8,9,10,11,12,13,14,15,16]. For instance, some authors proposed the direct oximation and rearrangement of ketones and in particular, of the cyclohexanone, to the corresponding amides [15,16,17,18,19,20]. The second important process in term of amide produced is the Hoechst-Celanese process for the synthesis of the N-acetyl-4-aminophenol (acetaminophen). The production of such an important drug is in continuous growth [21]. The existing processes are based on several type of reactions, one of the most employed is actually the Hoechst-Celanese process where 4-hydroxy acetophenone reacts with hydroxylamine giving the corresponding oxime, which rearranges to the N-acetyl-4-aminophenol in the presence of thionyl chloride [22]. In this case, two steps are necessary to carry out the synthesis: an oximation stage and the Beckmann rearrangement [22]. A simplification of the process can be attained by carrying out these two latter stages in one-pot [23]. During the last decade our research group, Luo and coworkers have published independently some papers where oximation and Beckmann rearrangement occur in one pot in high yield [15,16,17,18,19, 23]. The kernel of the process is using a mixture of trifluoroacetic acid and acetonitrile, which allows high yield in the amides [15,16,17,18, 23]. More recently, we pointed out that the two reactions, when the temperature is increased over 383 K, proceeds also in absence of trifluoroacetic acid (though in lower yield) and the reaction is self-catalyzed by the hydroxylammonium salt [24]. It appears (see Scheme 1) that the major weakness of this reaction is the use of hydroxylammonium salt as oximation agent (hydrochloride is the preferred), since a purification from hydrochloric acid or other mineral acid present in the reaction environment must be considered in an industrial application of the reaction.

Starting from these considerations, it is clear that the main concern of the whole one-pot process is strictly related to the hydroxylamine in the reaction environment, in fact, hydroxylammonium salt are sparingly soluble. For this reason the oximation process are slow, thus needs quite high temperature in order to achieve partial dissolution, for increasing formation of free oxime, and finally to speed up reaction rate [25]. Furthermore, it is necessary to take into account that the use of liquid hydroxylamine is not industrially desirable due to the intrinsic instability of the compound, which may cause devastating explosion in plants as already occurred in the CSI plant of Allentown Pennsylvania on February 1999 [26]. Nowadays, the industrial production of hydroxylamine arises mainly from three processes: Rashig, BASF-Inventa and HPO-DSM [27]. In any case, these processes are all based on the reduction of nitrites, NOx and nitric acid in solution of mineral acids, the latter stabilize the hydroxylamine produced to the corresponding hydroxyl ammonium salt [27]. The direct formation of hydroxylamine from ammonia oxidation is practicable by the direct amoximation of ketones by following the above-mentioned Eni process [1]. In this case, ketone consumes immediately the hydroxylamine produced by the oxidation reaction thus directly forming the oxime. Furthermore, the reaction occurs in an aqueous solution of isopropyl alcohol, which reduces the risk of decomposition and explosion of the hydroxylamine eventually in solution [1]. The use of such a solvent, however, in the amoximation process does not allow a further Beckmann rearrangement, particularly, by using the trifluoroacetic acid (as organocatalyst) in a one-pot process [15,16,17,18]. Then under such conditions, the recovery of the oximes from the solvent became necessary for the further step of Beckmann rearrangement. This further step diminishes the sustainability of the rearrangement catalyzed by trifluoroacetic acid in combination with an amoximation stage. Starting from these evidences, it appears that oximation of ketones is the weak stage of an all-liquid phase synthesis of amides in one-pot. In fact, either, direct oximation of ketones with a hydroxylammonium salt of a mineral acid, or their amoximation, do not let a direct Beckmann rearrangement step, but separation and purification step needs.

In this paper, we want to show some results on the synthesis and use of the ionic liquid hydroxylammonium trifluoroacetate as oximation agent for ketones in very mild condition. We want to show also the complete compatibility with a further step of Beckmann rearrangement catalyzed by trifluoroacetic acid. Finally, a very preliminary result on a modified HPO process for the synthesis of such an ionic liquid is also given. The final aim of this preliminary work is that of proposing a practical liquid phase salts free synthesis of caprolactam and amides in general.

2 Experimental

All solvents and reagents were employed as received without further purification. Trifluoroacetic acid 98% (TFA) Carlo Erba, cyclohexanone 99% (CON), acetophenone 99%, 4-Hydroxyacetophenone ≥ 98%, 2-hydroxyacetophenone ≥ 95%, 2-methyl-acetophenone ≥ 98%, 4-Br-acetophenone 98%, 4-NO2-acetophenone 98%, 2,4,6-trimethyl-acetophenone ≥ 98%, cyclohexanone oxime (COX), acetanilide, N-acetyl-4-aminophenol, caprolactam (CPL), trifluoroacetic acid (TFA) 99%, hydroxylamine hydrochloride (Cl–H) 99%, hydroxylamine Sulfate 99% (SO4-2H), hydroxylamine phosphate 99% (PO4-3H), diethyl ether (Et2O), acetonitrile, ethanol (EtOH), dimethyl carbonate (DMC), dichloromethane, tetrahydrofuran (THF), and dioxane were all Merck solvent grade products. Deuterated chloroform and deuterated acetonitrile were Merck products. Analyses of the reactions were carried out with gas chromatograph (GC) an Agilent 6890 equipped with FID or on chromatograph coupled mass spectrometer (GC–MS) Agilent 7890A equipped with a MS detector (Agilent 5975C) both instruments with a HP 5 column (I.D. 320 μm, 30 m long, same column in both the). Helium was employed as carrier under the following conditions: injector 523 K, detector 543 K, flow 1 mL min−1, oven 333 K for 3 min to 523 K at 15 K minute−1 and 523 K for 15 min. Calibration with standard solutions of the pure products allows the calculation of yield and selectivity. In order to verify the presence of thermo-labile substances some samples were analysed by HPLC (Perkin Elmer 250 pump, LC 235 diode array detector and a C 18, 5 μm, 4 mm i.d. 25 cm long column, using CH3CN-H2O as mobile phase, in isocratic CH3CN 70%, at 1 mL min−1). 1H and 13C NMR measurements were carried out in a Brucker Avance 400 II at 400 MHz and 100 MHz, respectively, in CDCl3, CD3CN or D2O as the solvent. Impedance measurements were carried out on a Solartron SI1260 gain phase analyzer, employing a Pt conductivity cell with a 0.998 cm−1 constant in water or acetonitrile as a solvent at a Hydroxylamine trifluoroacetate concentration of 0.05 mol L−1. DSC-TGA measurements were carried out on a Linseis TGA1000 in an aluminum crucible under an air flow of 100 mL min−1 and a temperature ramp of 10 K min−1. Electron spray mass spectrum (ESI–MS) where carried in a Waters Micromass ZQ by direct injection of a 1 ppm TAH solution in acetonitrile. Hydroxylamine trifluoroacetate were synthesized by an exchange procedure in aqueous solution. A typical preparation was carried out as follow: hydroxylamine sulfate was dissolved in water (c.a. 10 wt. %). A solution of Ba(OH)2 5% is neutralized with TFA plus an addition of a small excess of TFA until pH = 3, this is useful to complete the exchange of the sulfate ions in the second step. The slowly addition of the hydroxylammonium sulfate solution allow the precipitation of BaSO4 and in solution remains NH2OH·CF3COOH (TAH). The separation of the surnantant solution by centrifugation it allows recovering TAH after the evaporation of the water in a rotary-evaporator at 343 K under vacuum (mechanical pump 1000 Pa). The resulting viscous oil is then left at 343 K under higher vacuum (0.2 Pa) for 2 h. TAH is a viscous colorless liquid and it was characterized by TGA–DSC, NMR, and electric conductivity, the latter measurements states that the compound has an ionic conductivity (all the measurements are in supplementary materials).

All the reactions were carried out in a well stirred glass reactor thermostated at temperatures comprised between 298 K and 318 K, containing weighed samples of the solvent and reagents. In a typical experiment was loaded 10 mmol of the selected ketone, 30 mmol of NH2OH·X (where X = CF3COOH, HCl, H2SO4, H3PO4), 10 mL of solvent (CH3CH2OH, CH3CN, DMC, CH2Cl2), and, if required, 30 mmol of TFA, reaching the final volume of reaction of about 12 mL.

The Beckmann rearrangement step were carried out in the same reactor used for the oximation plugged into a 20 mL autoclave in order to accomplish Beckmann rearrangement at temperature of 383 K, which is higher than that of the boiling point of the solvent (acetonitrile 355 K).

Analysis of reaction products were carried by GC, GC–MS, HPLC and NMR. In the selectivity calculations TFA peak has not been considered, while the traces amount of the ester COX-TFA is added to the COX peack. The 1H and 13C NMR spectra were recorded at 298 K. NMR spectra were obtained from the mixture of reaction after purification by vacuum distillation. Typically, the product is an oil, which was washed with dichloromethane, dried with anhydrous sodium sulfate, and the solvent eliminated in a rotary evaporator. Spectra and analytical details in are supplementary materials.

Preliminary experiments of nitric acid hydrogenation in aqueous TFA as a solvent (12 mL of HNO3 0.25 mol L−1 in aqueous TFA at 10%) were carried out in an agitated glass reactor at 308 K for 8 h, at atmospheric pressure under hydrogen flow of 30 mL min−1. Nitric acid conversion and hydroxyl amine formation are measured by spectrophotometric analysis [28].

3 Results and Discussions

3.1 Influence of the Oximation Agent in the CON- > COX- > CPL Process

Oximation reaction is a nucleophilic one and the actual reagent is the NH2OH. As a matter of fact, in the usual organic synthesis the use of a strong base, such KOH or NaOH, it allows the neutralization of the acid of the hydroxylammonium salt, and the formation of free NH2OH with the consequent formation of a stoichiometric amount of the sodium or potassium salt of the acid. The high reactivity of the free NH2OH, though hydroxylammonium salt are sparingly soluble in non-aqueous organic solvent, allows the formation of the oxime. However, it arises at quite high temperature or long time of reaction. Table 1 shows the reactivity of different oximation agent on CON conversion to COX in acetonitrile as the solvent. It appears that practically only TAH achieves quantitative conversion after 1 h of reaction, either in the presence of TFA or in its absence (at longer time of reactions a very small increase of the condensation byproducts is observed about 2%). In the presence of other hydroxyl ammonium salts, reactions have shown lower conversion and selectivity. Only the reaction with Cl–H has reached 78% of conversion after 20 h of reaction. It is noteworthy the presence of TFA is mandatory to have in the second step, that is the Beckmann rearrangement of the oxime, high conversion and selectivity in CPL, for this reason we tested the reactivity of the various oximation agent in the presence of TFA in the optimal concentration for the Beckmann rearrangement [15,16,17,18]. The presence of TFA causes the reduction of the selectivity in COX especially at longer reaction time, because of the increases of the condensation products of CON catalyzed by TFA. In fact, CON, which is stable in acetonitrile solution at 298 K, in the presence of TFA, it shows condensation products (see Table 1). The reason of such a reactivity of TAH can be ascribed to its complete solubility in acetonitrile or in the mixture acetonitrile TFA. In addition, just the selectivity is unaffected by the presence of the TFA, while with other oximes decreases.

Table 2 reports the reactivity in the second step of the process that is the Beckmann rearrangement catalyzed by TFA or, eventually, by the acid deriving from the hydroxylammonium salt. It appears that only in the presence of an excess of TFA conversion to CPL occurs in practical interesting yield. As a matter fact, in the presence of TFA/COX = 3 it achieves practically quantitative conversion and selectivity of 97–98% in CPL after one hour of reaction only in the presence of TAH. In other cases, reactions appear incomplete (even though quite good results it is achieved after 20 h of reaction with Cl–H) and several condensation products of CON are in the reaction mixture after 20 h of reaction. The formation of such condensation products can be explained by the presence of unreacted CON, which causes these unwanted condensation reactions at the increasing of the temperature to 383 K, necessary to achieve a quite fast Beckmann rearrangement of the COX [15,16,17,18]. This agrees with the results of the control reactions carried out without oximes, in which CON condensations products are the only molecules detected. Besides, these side-reactions favors COX hydrolysis further, because of formation of water and alcohols, thus determining an extra reduction of the selectivity in CPL. The formation of condensation products are parallel reactions, since CON in the presence of TFA after 1 h of reaction at 383 K gives, a conversion of 8% to such condensation compounds. In addition, in the presence of hydroxylammonium salts and no TFA, COX forms mainly CON and its condensation products, while, if TAH is in reaction medium, it minimizes hydrolysis to CON together with its condensation products.

3.2 Influence of Solvents and of the Operative Variables on Oximation of CON with TAH Followed by Beckmann Rearrangement to CPL

Table 3 shows the influence of various solvents on the reactivity of the TAH in the CON oximation and Beckmann rearrangement. CH3CN as a solvent gives the best results, since in such a solvent both the oximation and the rearrangement steps occur easily. In the other tested solvents, the oximation takes place in high conversion and selectivity in COX, but the second step occurs in much lower conversion and selectivity. For instance, toluene, dioxane and THF shows a quite high selectivity in CPL but conversion of COX is very low, while in EtOH, DMC and Et2O CPL is formed only in few percent of yield. Toluene as the reaction solvent gives lower oximation yield (conversion 94% selectivity 98%), but it appears to be a good solvent for the second step where 96% selectivity to CPL is achieved. Actually, CH3CN appear to be however, the best solvent for such a process, this is in agreement with previous results in which specifically this solvent were recognized as the best solvent for the Beckmann rearrangement catalyzed by TFA [15,16,17,18].

3.3 Reactivity of TAH Towards Different Ketones

TAH shows high reactivity toward all ketones in the oximation reaction, in fact in all cases high conversion and selectivity is achieved in 1 h at 298 K. As expected 2,4,6 trimethyl acetophenone (2,4,6-TMA) does not react since the nucleophile does not approach to the carbonyl because of the steric hindrance of the methyl group in 2- and 6- position of the phenyl. This effect on the reactivity of the TAH is the same for the reactivity of the free hydroxylamine in aqueous solvent, in which the same steric effect with ortho- substituents were observed [29]. Such a behavior of the hydroxylamine as nucleophile suggests that the role of the trifluoroacetate is not determining the reactivity of the hydroxylamine itself, but, likely, it acts on the solubility of the ionic specie. In fact, a single phase is achieved with TAH while with the other hydroxylammonium salts a solid phase is always present.

From practical point of view it is noteworthy the high conversion and selectivity for the 4-OH-acetophenone (4-OHACP) would suggest a new route for the synthesis of acetaminophen (N’acetyl-4-aminophenol) in a waste free process and in one pot reaction [23]. In fact, the use of TAH will allow the synthesis of such a compound without salts coproduction and with a complete reuse of solvent and TFA.

In this table for the sake of clearness we report the reactivity of only the 2-MeACP (other isomers are in the supplementary materials Table S1) since both E and Z oximes are obtained and the reason of this difference with respect to the other ketones is beyond the aim of the present work and it needs further investigations (Table 4).

3.4 Preliminary Results on HNO3 Hydrogenation in TFA for the Direct Synthesis of TAH

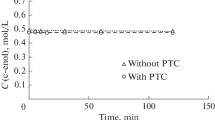

The use of TAH, as oximation agent for cyclohexanone as intermediate in the caprolactam production, is interesting, if it is available an easy way to obtain such a reagent without using complex procedure or multistep process. The HNO3 hydrogenation DSM-HPO process gives directly hydroxylamine phosphate salt, now we try to verify the feasibility of a modification of such a process in order to obtain directly the TAH by hydrogenation of the nitric acid [27]. In Fig. 1 a reaction profile of nitric acid hydrogenation is reported. It is noteworthy that there is a negligible difference in the reactivity of HNO3 or its sodium salt, suggesting sodium cation does not influence the overall reactivity. Conversion does not reach completeness after 8 h of reaction however at higher temperature and pressure a complete conversion is reached but at lower overall yield of TAH. As a matter of fact, complete hydrogenation of hydroxylamine to ammonium hydroxide occurs at higher temperature and pressure. The process appears a complex pattern of parallel and consecutive reaction whose optimization is beyond the scope of this preliminary work.

4 Conclusions

The reactivity of TAH and that of TFA for an integrated process from ketones to amides has been verified. It appears that TAH as oximation agent results generally more active than the mineral acid oxime salts. In fact almost all the ketones undergo oximation in 1 h at room temperature. The reason of such a behavior it has been ascribed mainly to the complete solubility of the compound in the various solvents employed for the reactions rather than to a specific reactivity of the ionic liquid. The more useful behavior of the compound in this consecutive reactions is however, the formation of TFA after the oximation step, which is necessary for the further step of Beckmann rearrangement. Furthermore, TFA does not negatively affect the oximation step and it can be added in quite large excess directly in the first stage of the process. The Beckmann rearrangement however occurs easily in the same reaction environment but temperature must be raised at 383 K to achieve complete conversion in 1 h of reaction. Finally the possibility of the synthesis of the TAH via a modified HPO process in which the ionic liquid can be obtained directly from HNO3 hydrogenation in the presence of TFA has been preliminarily demonstrated. Reuse of solvent and trifluoroacetic acid is easily achieved by distillation.

References

Rivetti F, Buzzoni R, in Liquid Phase Oxidation via Heterogeneous Catalysis: Organic Synthesis and Industrial Applications, Eds. Clerici M. G, Kholdeeva O. A, (Wiley New York 2013) 462–496.

Fisher WB, Crescentini L. Staff U, in Kirk Othmer Encyclopedya of Chemical Technology, Vol. 4 (Wiley New York 2015) 1–11 on line eds.

Bin S, Wei W, Enze M, Ye X (2007) China Pet Process Pe 7:25

Fisher G (2003) Fibers Text East Eur 11:1114

Van der Linde S, Fisher G (2004) Fibers Text East Eur 12:17

Kumar R, Prangya SS, Das P, Bhabavanbhai GGK, Al Fatesh A, Chowdhury B (2019) Catal. Rev. 61:516

Kaur K, Srivastava S (2020) New J Chem 44:18530

Karthikeyan P, Aswar SA, Muskawar PN, Sythana SK, Bhagat PR, Kumar SS, Satvat PS (2016) Arab J Chem 9:S1036

Crisalli P, Kool ET (2013) J org chem 78:1184

Marziano NC, Ronchin L, Tortato C, Vavasori A, Bortoluzzi M (2008) J Mol Catal A Chem 290:79

Ronchin L, Vavasori A, Bortoluzzi M (2008) Catal Commun 10:251

Ronchin L, Vavasori A, Bortoluzzi M (2008) J. Mol. Struct. Theochem 858:46

Ronchin L, Vavasori A (2009) J Mol Catal A Chem 313:22

Aricò F, Quartarone G, Rancan E, Ronchin L, Tundo P, Vavasori A (2014) Catal Commun 49:47

Rancan E, Quartarone G, Ronchin L, Vavasori A (2015) Catal Lett 145:939

Zhang JS, Riaud WAK, Lu YC, Luo GS (2014) Catal. Lett 144:151

Zhang JS, Lu YC, Wang AK, Luo GS (2013) Ind Eng Chem Res 52:6377

Quartarone G, Ronchin L, Tosetto A, Vavasori A (2014) Appl Catal A-Gen 475:169

Bianchini E, Pietrobon L, Ronchin L, Tortato C, Vavasori A (2019) Appl Catal. A-Gen. 570:130

Horlenko T, Fritch J.R, Fruchey OS to Hoechst Celanese Corporation, US pat. 4954652 (1990).

Quartarone G, Rancan E, Ronchin L, Vavasori A (2014) Appl Catal A-Gen 472:167

Rancan E, Aricò F, Quartarone G, Ronchin L, Tundo P, Vavasori A (2014) Catal Commun 54:11

Pietrobon L, Ronchin L, Sadraoui C, Pontello R, Tosetto C, Vavasori A (2020) Appl. Catal. A-Gen. 598:117570

Long LA, (2004) Process Saf. Prog. 114.

H. Ritz, H. Fuchs, H. G. Perryman, “Hydroxylamine” in Ulmann’s Encyclopedia of Industrial Chemistry, 18 (2000) 503–509, Wiley on line eds.

Jones RN, Thorn GD (1949) Canadian J of Res 27:580

Marziano NC, Ronchin L, Tortato C, Tonon O, Bertani R (2004) Int J Chem Kinet 36:417

Funding

Open access funding provided by Università Ca' Foscari Venezia within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Manente, F., Pietrobon, L., Ronchin, L. et al. Trifluoroacetic Acid Hydroxylamine System as Organocatalyst Reagent in a One-Pot Salt Free Process for the Synthesis of Caprolactam and Amides of Industrial Interest. Catal Lett 151, 3543–3549 (2021). https://doi.org/10.1007/s10562-021-03590-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03590-z