Abstract

Here we report some results on a 3 steps benzene caprolactam process via amination, aniline Hydroxymation and Beckmann rearrangement. The amination proceeds with hydroxylamine trifluoroacetate, with 97% of conversion and selectivity of 90%, catalyzed by V compounds. We achieve 98% of conversion and 95% of selectivity in the hydroxymation of aniline in the presence of hydroxylamine trifluoroacetate, sulfonic resin and Pd/C. While in the absence of the resin, hydrogenation of hydroxylamine trifluoroacetate occurs readily to the ammonium salt. The reaction occurs likely by the exchanged hydroxylamine and the aniline reduction intermediate. The use of hydroxylamine trifluoroacetate, instead of the chloride, favors the sustainability of the process by avoiding the ammonium chloride formation. The absence of salt except those derived from the trifluoroacetic acid allows a complete reuse of the trifluoroacetic acid and the only byproduct is ammonium nitrate obtained by resin regeneration. Beckmann rearrangement of the so produced cyclohexanone oxime occurs easily after diethyl ether evaporation and additions of a solution trifluoroacetic acid acetonitrile in high yield and selectivity.

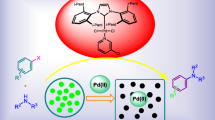

Graphical Abstract

New three steps caprolactam process via benzene amination and aniline hydrogenation.

Similar content being viewed by others

1 Introduction

Caprolactam processes are all centered on the Beckmann rearrangement of the cyclohexanone oxime, even the photonitrosation of cyclohexane commercialized by Toray passes through the Beckman rearrangement of a nitrosyl intermediate, which is in equilibrium with the cyclohexanone oxime [1]. In all processes considered, there is coproduction of salts, and only in the last decade are operative salt free processes in the Far East, employing a step of cyclohexanone amoximation and a second one of a gas phase Beckmann rearrangement [2, 3]. These processes, which are licensed by Eni-Sumitomo and China Petrochemical Co. appear to be highly sustainable, but they have had a development of new plants only in China [4]. On the contrary, Sumitomo very recently announce its exit from caprolactam business [5].

Despite the development of these new processes, several companies such as BASF, China Petroleum & Chemical Co., Honeywell International, UBE Industries, employ stoichiometric processes, where ammonium sulfate is quantitatively the main product [1]. An interesting process is the HPO Fibrant (ex DSM), which has actually 25% of the market, this highly optimized liquid phase route allow the lower coproduction of phosphate and sulfate salts, but at the expense of complex recycling of both organic and inorganic stream [6]. The Global Caprolactam Market size was USD 13.7 Billion in 2020 and expected to reach USD 14.7 Billion in 2022, despite of Sars-cov 19 pandemic scenario started in 2020, a production growth rate of 4–5% is forecasted until 2030 [7]. It appears that a complete change of the traditional plants based on liquid phase reactions seems to be not justified in Europe and in the USA since the caprolactam demand in the western region does not growth as in the Far East [1, 8,9,10]. Anyway, after all these considerations, the revamping of existing plant in Europe and USA could be a more sustainable route, with respect to the construction of new ones.

Hydrogenation of phenol is a classical route for the synthesis of cyclohexanone, which is the starting material for the production of the cyclohexanone oxime [1]. The phenol hydrogenation, is a cleaner way to the cyclohexanone oxime synthesis, however the phenol produced by the Hock process derive from a multistep with quite low overall yield from benzene. Furthermore, the demand of phenol and the coproduction of acetone, whose market value is not comparable with that of phenol, are bottlenecks for a caprolactam production based on this synthetic path [11, 12]. Starting from such a point of view, the use of nitrobenzene as starting material for cyclohexanone oxime production looks like competitive compared to both phenol hydrogenation and cyclohexane oxidation. In fact, nitration of benzene gives nitrobenzene in one-step only. The reaction is selective and obtained in high yield. Furthermore, it could be easily carried out both in continuous and batch operations [13]. For these reasons, the recent studies of nitrobenzene hydrogenation to cyclohexanone oxime appear to open a promising perspective to alternative routes in the COX production, without a complete change of plant layout [14,15,16]. In Scheme 1 is reported the process from nitrobenzene to caprolactam occurring at very mild condition 338 K and 5 bar.

On the other hand, the reaction proceeds in very high yield, directly starting from aniline [16]. The reaction appears to be highly selective to cyclohexanone oxime, thus aniline hydrogenation to cyclohexanone oxime step is the key for the overall process [16]. In addition, the presence of the hydroxylamine is necessary not only as the reagent for the formation of the COX, but it appears to be a promoter in the hydrogenation of the aniline itself [16]. In fact, formation of COX occurs on the catalyst surface by the reaction of a Pd-imine complex with the hydroxylamine [16]. Then, a further improvement on the overall process could be the use of aniline as starting reagent. In fact, the production of the cyclohexanone oxime, integrated with a process of benzene amination may represent a step forward in the sense of a more sustainable process [17, 18].

A comparison of the overall yield from benzene to caprolactam (CPL) of the main industrial process could be useful to focus on the sustainability of the various procedure [1, 11,12,13, 19]. Table 1 reports the data available for the different processes [1, 11,12,13, 19]. It is evident that the direct conversion from benzene to CPL is accompanied by a large amount of byproducts and several steps (6 in all the process), mainly due to the synthesis of cyclohexanone [1, 11,12,13, 19]. Nitrobenzene process shows the best performance in the reduction of the number of steps and the overall yield from benzene, but lacks in reduction of byproducts.

A further drawback of a process via benzene nitration is that, such a reaction is poorly sustainable and definitely not green. For this reason, its substitution with a single step amination reaction is an ambitious target for the aromatic amines industry [17]. The use of huge amounts sulfuric acid, with the consequent acid dilution and re-concentration stages necessary in the purification of the product, causes corrosion, environmental and economic concerns [13]. Undoubtedly, a new process, where a step starts with such a problem, is not appealing for the revamping of existing plants, since its sustainability is not entirely justified from purely economic perspective. Actually, the reduction of reaction steps does not gain a substantial benefit from an environmental point of view [14, 16]. Even though, benzene amination is a valuable alternative for aniline production it is not an easy way [17]. In fact, in the early work of Kovacic and Bennet reactions took place at 373 K and using strong Lewis acid with low amines yield [18]. More recently are reported yields of 60% in aniline at 353 K, in the presence a high load of V(IV) as the catalyst, with TONs of 30–40 after 4 h of reaction, these evidences suggests that reaching high yields in this reaction is a hard target [20]. In fact, aniline synthesis appears to be the key step of a benzene to caprolactam process via aniline, but it is sustainable when amination reaches a yield comparable to those of nitration-reduction steps, thus avoiding the nitrobenzene synthesis. Furthermore, amination of benzene with hydroxylamine could be sustainable in an optic of an integrated process. Hydroxylamine acts as amination and oximation agent but its production in large amount by salt free processes is necessary for the sustainability of the process. In fact, aniline synthesis appears to be the key step of a benzene to caprolactam process via aniline, but it is sustainable when amination reaches a yield comparable to those of nitration-reduction steps, thus avoiding the nitrobenzene synthesis.

Recently, the cyclohexyl amine oxidation route to CPL has been reproposed, such an interesting reaction needs, however the synthesis of such an amine which is a not straightforward. Actually, aniline hydrogenation is not easy and the yield to cyclohexyl amine are obtained by using more severe conditions than that employed in the hydrogenation of AN to COX [21,22,23].

During the last decades have appeared in literature some papers where the Beckmann rearrangement of oximes occur easily in high yield at temperature of 353–373 K in the presence of trifluoroacetic acid [24,25,26,27,28]. The kernel of these processes is the use of a mixture of trifluoroacetic acid and acetonitrile, which gives high yield in the amides [24,25,26,27,28]. More recently has been introduced a one-pot process where ketones oximation and Beckmann rearrangement where carried out in the same reactor in one-step in the presence of TFA and hydroxylamine hydrochloride in the same range of temperature of the Beckmann rearrangement [29,30,31,32,33]. In addition, we pointed out that the two reactions, at higher temperature (383–393 K), proceeds also in absence of trifluoroacetic acid (though in lower yield) and hydroxylammonium salt is self-catalyzes the reaction [33].

Nevertheless, in all the processes until described, the elimination of hydrochloric acid or ammonium chloride is certainly their major limit. Recently, we showed that the use of the ionic liquid hydroxylamonium trifluoroacetate instead of an inorganic hydroxylamine salt, results in salt free process giving high yield of caprolactam starting from cyclohexanone [34]. In this case, the purification from hydrochloric or from other mineral acids is avoided, so that resulting in a more efficient process both from environmental and industrial point of view [34].

The use of sulfonated resins as catalyst or absorber is well known for long time. For instance, these type of materials as catalysts for ethers and esters are commonly used in the synthesis of methyl tert-butyl ether or in transesterification of vegetal oil in biodiesel production. [35, 36]. O-alkylation of phenol with cyclohexene shows the need of a protic molecule thus allowing the proton exchange between the resin and the olefin in order to form a surface polarized adduct, which is responsible of the catalysis [37]. Besides, in the hydration of olefins promoted by TFA the sulfonated resin as esterification and hydrolysis catalyst grants an enhancement in the yield of the desired products [38].

In this paper, we want to show some results on the use of hydroxylammonium salts in the benzene amination catalyzed by various metals. In addition, we propose the selective Hydroxymation of nitrobenzene and aniline to cyclohexanone oxime catalyzed by Pd/C catalyst. Finally, the Beckmann rearrangement of the cyclohexanone oxime in TFA demonstrates the feasibility of a benzene CPL process in three steps. The formation of ammonium ion as byproduct of the process is a drawback, but it could be the base for a regenerative ammonium nitrate/nitric acid/trifluoroacetic acid exchange process to be used in a modified HPO process, which we have reported some preliminary results in a previous paper [34].

2 Experimental

All solvents and reagents were employed as received without further purification. Trifluoroacetic acid 98% (TFA) Carlo Erba, cyclohexanone 99% (CON), cyclohexanone oxime (COX), caprolactam (CPL), aniline 99% (AN), Nitrobenzene 99% (NB), hydroxylamine hydrochloride (HA.HCl) 99%, hydroxylamine Sulfate 99% (HA.H2SO4), hydroxylamine phosphate 99% (AH.H3PO4), acetonitrile, ethanol (EtOH) and diethyl ether (DEE) were all Merck solvent grade products. Iron and cuprum powder are Carlo Erba PA products, Ammonium vanadate 99%, Sodium vanadate a Merck product. Pd/C 5% is an Engelhard (now Basf catalyst) Escat 10. Amberlyst 15 and 36 (4.7 and 5.8 meq H+/g, respectively) are Merck products.

Hydroxylamine trifluoroacetate (HA·TFA) were synthesized by an exchange procedure in aqueous solution. A typical preparation were carried out as follow: hydroxylamine sulfate was dissolved in water (c.a. 10 wt%). A solution of Ba(OH)2 is neutralized with TFA plus an addition of a small excess of TFA until pH 3, this is useful to complete the exchange of the sulfate ions in the second step. The slowly addition of the hydroxylammonium sulfate solution allow the precipitation of the BaSO4 and in solution remains HA.TFA. The separation of the surnantant by centrifugation it allows recovering HA-TFA after the evaporation of the water by a rotary-evaporator at 343 K under vacuum (mechanical pump 1000 Pa). The resulting viscous oil is then left at 343 K under higher vacuum (0.2 Pa) for 6 h. A previous paper reports the characterization of HA·TFA by NMR, and electric conductivity [34].

The amination reactions have been carried out in a in an autoclave equipped with a glass insert, stirred by magnetic agitation and fluxed with nitrogen and/or air, then heated in a thermostated oil bath at the reaction temperature (353 K). In a typical reaction, 5 mmol of hydroxylamine and 0.1 mmol of catalyst were dissolved in 10 mL of water/acetic acid 1/9 solution as a solvent. Then 5 mmol of substrate is added to the solution at the temperature of reaction. Some reactions with HA·TFA were carried out in the absence of water, since it is soluble in neat acetic acid. After 4 h of reaction, the solution is neutralized with NaOH, extracted with DEE, finally analyzed by GC, HPLC and GC–MS.

All the hydroxymation reactions were carried out in an autoclave equipped with a glass insert, stirred by magnetic agitation, thermostated at temperatures comprised between 323 and 353 K, containing weighed samples of catalyst, promoter, solvent and reagents. Typically 10 mmol of nitrobenzene or aniline, 30 mmol of HA·X where X = CF3COOH, HCl, H2SO4, H3PO4, 10 mL DEE as the solvent, 2 g of sulfonated styrene–divinylbenzene copolymers, 50 mg of Pd/C 5%, finally the volume of reaction is about 12 mL.

The Beckmann rearrangement step were carried out in the same reactor used for the oximation step plugged into a 20 mL autoclave in order to accomplish Beckmann rearrangement at temperature of 383 K, which is higher than that of the boiling point of the solvent (acetonitrile 355 K). A typical experiment consists on removing the solid by filtration and the solvent by evaporation at 298 K overnight. Finally 20 mL TFA (30 mmol) in acetonitrile was added to the residue, the autoclave is closed, washed with nitrogen, and finally heated at 383 K for 2 h. The reaction solution were neutralized with NaHCO3 before the analysis. In some experiments, we distilled the solvent and recovered both TFA and acetonitrile.

Analysis of reaction products were typically carried by gas chromatograph (GC), gas chromatograph coupled with mass spectroscopy (GC–MS). Besides, we checked products and reagents by high performance liquid chromatography (HPLC).

3 Results and Discussion

This work is divided in three part the first one is the amination of benzene, in these experiments the reactivity of various metal catalysts are tested under the run conditions similar to those available in literature [20]. The second part is under many aspects alike to that reported in a recent paper in which the investigation has regarded mainly the conditions of reaction and the stages of the overall process [20]. Here, however, we investigate a different aspect that is the use of the trifluoroacetyl hydroxylamine in the synthesis of cyclohexanone oxime in the presence of a sulfonic resin. In addition, we verify the feasibility of the whole transformation from benzene to CPL by testing the various steps of the process sequentially.

3.1 Some Results on Benzene Amination with Hydroxylamines

Table 2 reports some preliminary results on amination of benzene. In this reaction, catalyst is homogeneous in aerated acetic acid solution. The yield of aniline reaches almost 34% of conversion and 98% of selectivity using NaVO3 as a catalyst (entry 1). NH4VO3 (entry 2) as a catalyst shows lower selectivity and conversion than NaVO3. Fe and Cu both show low conversion compared to V, thus suggesting a lower activity of these metals (entries 3 and 4). An interesting feature of the utilization of HA·TFA instead of HA·HCl is the high solubility of this ionic liquid in organic solvent, thus it is feasible its use neat acetic. In fact, the use of neat acetic acid is most relevant improvement, since all the metals tested show an increasing of their activity by using acetic acid instead of the aqueous acid solution.The reaction carried out in the presence of HA·TFA has, in any case, higher conversion and selectivity than those reactions carried out in HA·HCl (entries 5–10). Despite of these very preliminary results on benzene amination, it appears that the use of HA·TFA together with NaVO3 as catalyst gives remarkable yield in aniline thus suggesting the possibilities for a new integrated process, HA·TFA, benzene to caprolactam. The best result is obtained in the presence of NaVO3 with NH2OH.TFA as amination agent, in neat acetic acid with a conversion of 76%, selectivity of 97% and a TON of 38 (entry 6). To say the truth it is actually a modest utilization of the catalyst, however comparable of what reported in literature [20]. Entry 7 has been carried out in the presence of an equimolar amount of V in order to verify if it is possible to achieve high aniline yield. In this case, we obtain almost quantitative conversion and selectivity above 90%, suggesting the possibility of a synthetic application. Further studies need for the reuse of the vanadium catalyst.

The reactivity of other aromatics, the optimization of the run conditions and the study of the mechanism are beyond the scope of the present work.

3.2 Nitrobenzene and Aniline Hydrogenation in the Presence of Various Hydroxylamonium Salts

In Tables 3 and 4, we compare the hydrogenation of nitrobenzene and aniline in the presence of several hydroxylamonium salts. As already pointed out in the previous paper, nitrobenzene hydrogenation is faster than that of the COX formation from aniline [16]. The latter derives easily from nitrobenzene but COX needs longer reaction time. The best results are, in any case observed, in the presence of the hydrochloric salt (entries 1 and 2). At difference of the mineral acid hydroxylammonium salts, HA.TFA, in the range studied, is fully soluble in DEE, but the selectivity to COX is negligible. The presence of a soluble hydroxylamonium salt is accompanied by a fast hydrogen consumption (see Sect. 3.3) due to parallel hydrogenation of nitrobenzene and of hydroxylamine, the reaction is highly selective to AN and only in negligible amount to COX (entries 3 and 4). Thus suggesting the fast parallel reaction of hydroxylamine hydrogenation causes a fast lowering of its concentration, thus determining the low selectivity in COX. On the contrary, the very low selectivity to COX in the presence hydroxylamine sulfate and phosphate compared to the chloride one can be ascribed to the negligible solubility of these salts and likely to the inhibiting effect of sulfate and phosphate anion.

The use of AN as the starting substrate shows low yield in COX, except the reaction carried out in the presence of HA.HCl (Table 4 entries 1 and 2). Such a behavior can be ascribed, as already suggested for NB hydrogenation, to the solubility of the hydroxylamines, which is complete for the HA.TFA being hydrogenated to the ammonium salt, while results negligible for sulfate and phosphate ones. It is noteworthy the lower conversion of the aniline compared to the reactions of Table 3, where aniline is converted to COX after the reduction of the nitro-group [16]. Such a phenomenon can be ascribed to a strong deactivating effect of the AN on the catalyst activity, when Pd directly interact with the amine, as already pointed out in a previous work [16].

3.3 Hydrogenation of Nitrobenzene and Aniline in the Presence of Sulfonic Resins

After such a comparative introduction on the reactivity of the various hydroxylamonium salts in the synthesis of COX, we reports in Table 5 some results obtained in the hydrogenation of nitrobenzene also in the presence of a macro reticular sulfonic resin. The use of two different resins show similar results suggesting a minor influence of the type of resin on the overall reactivity. As regard the reactions in the presence of HA.HCl (entry 1 and 2) it appears that after 20 h of reaction the reactivity is similar to that observed without the resins, thus suggesting the presence of resin does not change the behavior of the reaction. The reactivity of HA.TFA (entries 3 and 4) is similar to that of HA.HCl but completely different of that obtained without resin (Table 1 entries 3 and 4). Such a difference can be related to the hydroxylamine adsorption on the resin. In fact, the resin adsorbs hydroxylamine thus reducing its hydrogenation, in turn, the formation of ammonia displace the hydroxylamine from the sulfonic resin, thus allowing its reaction with the surface imine compound that is likely formed on the Pd catalyst [14]. The adsorption of HA on the resin has been tested by filtering away the resin and adding 10 ml 1 M NaOH solution, which readily displace the adsorbed base on the sulfonic site of the resin. In fact, the so obtained surnantant reduces a Fe(III) solution to Fe(II), clearly evidenced by the formation of the red complex with the 1,10-fenantroline. Furthermore, an ionic HPLC analysis of the solution shows the presence of both hydroxyl ammonium and ammonium ion, detailed study on HA adsorption on sulfonic resins is however beyond the aim of this research. It is noticeably that the reaction take place also in the presence of hydroxylamine exchanged on Amberlyst 15 or 36 (entries 5 and 6). Such an evidence suggests the reaction is strongly influenced by the effective concentration of the hydroxylamine, in fact, when hydroxylamine is dissolved into the solvent the reaction does not give COX but reaction stops to AN. This is due to the fast parallel reduction of HA, which is competitive with that of NB hydrogenation, then its consumption determines a negligible selectivity toward COX. Besides, we obtain similar behavior of reactivity for sulfate and phosphate hydroxylamonium salts of those observed without resins (compare Table 3 entries 5–8 with Table 5 entries 7–10).

Similar yields in COX are observed starting from AN instead of NB, in the presence of HA.HCl (Table 6 entries 1 and 2). This evidence, as already reported in a previous paper, demonstrates the consecutive nature of nitrobenzene reduction to AN and its further conversion to COX [16]. On the contrary, by comparison data of Table 4 with those of Table 6 we can easily gather that hydroxylamine reduction is a parallel hydrogenation reaction. In fact, if the sulfonic resin adsorbs HA.TFA from the solution, thus protecting HA of being quickly hydrogenated (compare Table 4 entries 3 and 4 with Table 6 entries 3 and 4). It appears that resin/HA equilibrium permits a concentration of HA sufficient for reacting on Pd surface with the imine intermediate to give COX [16]. Such a hypothesis is supported by the evidence that the reactivity of resins exchanged with hydroxylamine are comparable to those carried out in the presence of HA.HCl-resin or HA.TFA-resin and with comparable yields in COX (compare entries 1–4 with 5 and 6). Nevertheless, HA.H2SO4 and HA.H3PO4, as already observed without resin, give low selectivity in COX and the type of resin has no influence on the reactivity. Also in this case the reason of this behavior can be ascribed likely to the very low concentration of HA in solution not sufficient to react to give COX, together with a deactivating effect of the anions on the HA reactivity.

As already pointed out in previous papers, the amount of Pd/C catalyst is critical to achieve high yield in aniline [16]. Actually, in an experiment (entry 11) we loaded 4 times the amount of catalyst into the reactor reaching in this way a conversion of 96% and with a selectivity of 95%.

3.4 Comparison of the Hydrogen Consumption Rate of Nitrobenzene, Aniline and Hydroxylamonium Salts in the Presence of Sulfonic Resins

In Fig. 1, we compare the hydrogen consumption of nitrobenzene hydrogenation in the presence and without resin. As already pointed out in an earlier paper, two distinct behaviors characterize hydrogen consumption, in the first part we can observe a fast pseudo zero order reaction where nitrobenzene is hydrogenated to aniline and a second slower part, where aniline is converted to COX [16]. The presence of the resins does not modify such a behavior; the main difference with the previous research in the absence of sulfonic resin is a lower hydrogen consumption in the part of the NB reduction while in the conversion of AN to COX there is a substantially similar rate of reaction. The adsorption of hydroxylamine on the resin may explain the lower hydrogen consumption rate because of the presence of the resin almost completely stop the parallel hydroxylamine reduction.

In order to verify the role of the resin in the reduction of the HA.X we compare (see Fig. 2) the difference in the hydrogen consumption profile of various hydroxylammonium salts with and without Amberlyst 15 as a sulfonic resin (there are practically no differences with Amberlyst 36). It is noteworthy the reaction does not proceed noticeably in the presence of hydroxylammonium sulfate and phosphate, on the contrary the reaction occurs in the presence of HA.TFA and HA.HCl. The reaction carried out with HA.TFA appears very fast, thus explaining the very high selectivity in COX since hydrogenation of the oxime occurs faster than the reaction with the aniline. The slower reaction observed for HA.HCl is likely due to the lower amount of free HA in solution. In fact, HA.TFA is completely soluble, while HA.HCl is present mainly as a solid in the reaction environment. The presence of the Amberlyst 15 practically suppresses the reaction, as can be observed by the negligible amount of hydrogen consumed. Analogously, hydroxylamine exchanged on the resins shows a similar but very low amount of hydrogen consumption. This evidence suggests the absorption equilibrium of hydroxylamine is displaced toward resin, that is, the large part of the hydroxylamine is not in solution. Besides, by putting together an equimolar amount of Amberlyst 15/HA.TFA in DEE it appears that practically HA neutralizes all the sulfonic groups and the hydroxylamine is almost completely removed from the solution, remaining less than 3% of the initial concentration.

3.5 Direct Beckmann Rearrangement of the Hydrogenation Products

The reacted product of the nitrobenzene and aniline hydrogenation after the solid separation and the removal of the solvent, the latter operation is necessary to adding the solution of TFA in acetonitrile. Such a mixture of solvents gives the best results in the Beckmann rearrangement at 383 K, while reactions carried out in solution TFA DEE show both low conversion and negligible selectivity [21,22,23, 34]. Table 7 shows the results of the Beckmann rearrangement of the COX deriving from the hydrogenation reaction mixture. Because of the Beckmann rearrangement at 383 K is quite fast, all reactions have been stopped after 2 h of reaction, and can be considered at completion [23]. As expected the Beckmann rearrangement proceeds in high yield to CPL, the presence of aniline does not influence the reactivity of TFA since the acid is in large excess.

3.6 Reactivation of Sulfonic Resins with Nitric Acid and Recovery of Ammonium Nitrate and Pd/C Reuse

The recovery of the resins is a crucial point in the whole process, for this reason we tested the reusability of the resins after the adsorption of the ammonium from the reaction environment. It is noteworthy that the presence of the resin shows that the solid salt, which is coproduced during the reaction, is not observed because it is exchanged with the sulfonic sites of the resin. Washing the resin with 0.1 mol L−1 nitric acid allows to restore the sulfonic acid sites with negligible loss in acidity of the resin (acidity was tested by titration, and the presence of HA in solution by Fe(III) reduction). The use of nitric acid to restore the acidity of the resins is justified since ammonium nitrate is a byproduct of not negligible value, whose employment as fertilizer is well known, in addition it could be reused in the HPO Fibrant process of hydroxylamine production [4].

Pd/C catalyst is the most expensive component of the whole process for such a reason its reuse in the reaction is of paramount importance for the sustainability of the process. The activity of the catalyst has been maintained after 4 reaction cycles. The Pd/C catalyst is recovered by filtration washed with plenty of water, ether and finally with water and desiccated at 363 K for 24 h before the use. After the operation of washing, which causes some losses, we carried out the reaction at constant substrate/Pd ratio by reducing the reaction volume. Figure 3 shows that activity and selectivity after 4 run are unaffected.

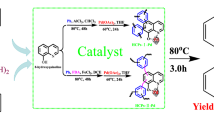

3.7 Single Reaction Carried Out at Maximal Yield

As can be observed in previous sections we studied the influence of various parameters on the yields of the various steps. The amination carried out in an equimolar amount of catalyst in the presence of HA.TFA and neat acetic acid shows almost quantitative benzene conversion and selectivity to aniline of 92%. The reaction under such a condition appear worth to be used in an amination process despite the stoichiometric use of NaVO3. In addition, as already observed in a previous paper, the yield to cyclohexanone oxime in the Hydroxymation step raises, by increasing the amount of Pd/C catalyst [14,15,16]. Besides Beckmann rearrangement catalyzed by TFA has been extensively studied in previous papers, we report in Table 8 the best result of such a study [23]. In fact, the yield in CPL of the whole process with respect to the starting benzene is about 79% being the synthetic path, which shows the highest overall benzene based yield to CPL. The main industrial processes (see Table 1) have, in any case a lower overall yield because of to the multistep processes from benzene to cyclohexanone. In addition, for a process based on these reactions path, the unwanted salt byproduct is only 0.5 weight ratio with CPL. From this point of view, the main byproduct of salts amount depends for the larger part by the HA·TFA synthesis. For such a reason, in order to improve further the sustainability of this process, we have recently proposed a modified DSM-HPO process for HA·TFA synthesis via nitrate hydrogenation, which gives directly HA·TFA without unwanted byproducts (some preliminary results of this reaction appeared in a previous paper) [16]. Finally, the need of a large excess of HA.TFA in the hydrogenation step is likely the major concern of the process, new selective hydrogenation catalysts may help to overcome such a problem.

4 Conclusions

We propose a new reaction path from benzene to caprolactam in three steps as reported in Scheme 2. The first stage is the amination of benzene promoted by V complex. The employ of HA.TFA allows the use of glacial acetic acid as a solvent, thus increasing the yield of AN above 90%, which is likely the highest, reported in literature.

The hydrogenation of AN to COX in the presence of Pd/C, sulfonated resins and HA.TFA instead of NB looks like a step further for the sustainability of the process, since the use AN, obtained by the previous amination step, allow to overcome benzene nitration. The reaction results selective to COX, but the parallel HA reduction limits its yield. The use of HA.TFA in the presence of a sulfonated resins shows a quite better utilization the HA improving the yield in COX, since the exchange of HA on the resin removes the hydroxylamine from the solution, thus avoiding its hydrogenation. The process may proceed by two simple steps: solvent removal and TFA addition, giving finally the CPL by Beckmann Rearrangement as the target product. The comparison with the actual processes (see Table 1) shows a neat diminish of the reaction steps and a substantial reduction of salts byproducts, without the use of sulfuric and nitric acid. Furthermore, all reactions are carried out in solution at moderate temperatures (333–383 K), thus allowing an easy revamping of the existing plants, since no complex equipment should need for their modification. Further improvements need however on the benzene amination step and on HA.TFA utilization being actually the main limits for the development of a new process.

References

Tinge J, Groothaert M, op het Veld H et al (2018) “Caprolactam” in Ullmann’s encyclopedia of industrial chemistry. Wiley on line Library. https://doi.org/10.1002/14356007.a05_031.pub3.

Tonti S, Roffia P, Gervasutti V (1992) Enichem Anic S.p.A., EP 0496385A1

Holderich WF, Dahloff G, Ichihashi H, et al (2003) Sumitomo Chemical Company US Pat. 6531595 B2.

Zong B, Sun B, Cheng S et al (2017) Green production technology of the monomer of nylon-6: caprolactam. Engineering 3:379–384

Tullo A (2022) Sumitomo will exit caprolactam business. C & EN 100(14):10

https://www.mordorintelligence.com/industry-reports/caprolactam-market

Cui X (2009) Market analysis of caprolactam at home and abroad. Fine Special Chem 17:30–35

Fisher G (2003) No rooms for new caprolactam plants. Fibers Text East Eur 11:14–15

Van der Linde S, Fisher G (2004) The caprolactam business must change: new production plants cannot be justified. Fibers Text East Eur 12:17–18

Weber M, Weber M, Volker Weber V (2000) Phenol. In: Ullmann’s encyclopedia of industrial chemistry. Wiley on line Library, https://doi.org/10.1002/14356007.a19_299.pub3.

Weber M, Pompetzki W, Bonmann R, Weber M (2004) Acetone. In: Ullmann’s encyclopedia of industrial chemistry. Wiley on line Libraryhttps://doi.org/10.1002/14356007.a01_079.pub4

M. Dugal (2005) Nitrobenzene and nitrotoluenes. In: Kirk-Othmer encyclopedia of chemical technology. Wiley on line. https://doi.org/10.1002/0471238961.1409201801041109.a01.pub2

Rubio-Marques P, Hernandez-Garrido JC, Leyva-Perez A et al (2014) One pot synthesis of cyclohexanone oxime from nitrobenzene using a bifunctional catalyst. Chem Commun 50:1645–1647

Corma A, Leyva-Perez AA, Rubio-Marques P (2014) Università politecnica de Valencia. WO 191589 A1.

Pietrobon L, Ronchin L, Sadraoui C et al (2020) Pd/C Catalyzed selective hydrogenation of nitrobenzene to cyclohexanone oxime in the presence of NH2OH·HCl: influence of the operative variables and insights on the reaction mechanism. Appl Catal A: Gen 598:117570

Chiara JL (2005) Vinyl- and Arylnitrogen Compounds. In: Katritzky AR, Taylor RJK (eds) Comprehensive organic functional group transformations II. Elsevier Science, Amsterdam

Kovacic P, Bennett RP (1961) Aromatic amination with hydroxylamine-O-sulfonic acid. J Am Chem Soc 83:221–224

Musser MT (2011) Cyclohexanol and cyclohexanone. In: Ullmann’s encyclopedia of industrial chemistry. Wiley on line Library. https://doi.org/10.1002/14356007.a08_217.pub2

Zhu LF, Guo B, Tang DY et al (2007) W Sodium metavanadate catalyzed one-step amination of benzene to aniline with hydroxylamine. J Catal 245:446–455

Greenfield H (1964) Hydrogenation of aniline to cyclohexylamine with platinum metal catalysts. J Org Chem 29:3082–3084

Chatterjee M, Sato M, Kawanami H et al (2011) Hydrogenation of aniline to cyclohexylamine in supercritical carbon dioxide: significance of phase behavior. Appl Catal A general 396:186–193

Liu S, You K, Song J et al (2018) Supported TiO2/MCM-41 as an efficient and eco-friendly catalyst for highly selective preparation of cyclohexanone oxime from solvent-free liquid phase oxidation of cyclohexylamine with molecular oxygen. Appl Catal A General 568:76–85

Marziano NC, Ronchin L, Tortato C et al (2008) Catalyzed Beckmann rearrangement of cyclohexanone oxime in heterogeneous liquid/solid system: part 2: influence of acid catalysts and organic promoters. J Mol Catal A Chem 290:79–87

Ronchin L, Vavasori A, Bortoluzzi M (2008) Organocatalyzed Beckmann rearrangement of cyclohexanone oxime by trifluoroacetic acid in aprotic solvent. Catal Commun 10:251–256

Ronchin L, Vavasori A, Bortoluzzi M (2008) A DFT study on secondary reaction pathways in the acid-catalysed Beckmann rearrangement of cyclohexanone oxime in aprotic solvent. J Mol Struct Theochem 858:46

Ronchin L, Vavasori A (2009) On the mechanism of the organocatalyzed Beckmann rearrangement of cyclohexanone oxime by trifluoroacetic acid in aprotic solvent. J Mol Catal A Chem 313:22

Quartarone G, Rancan E, Ronchin L et al (2014) Beckmann rearrangement of acetophenone oximes to the corresponding amides organo-catalyzed by trifluoroacetic acid for sustainable NSAIDs synthesis. Appl Catal A-Gen 472:167–177

Aricò F, Quartarone G, Rancan E et al (2014) One-pot oximation–Beckmann rearrangement of ketones and aldehydes to amides of industrial interest: acetanilide, caprolactam and acetaminophen. Catal Commun 49:47–51

Aricò F, Quartarone G, Rancan E et al (2014) Self-catalyzed direct amidation of ketones: a sustainable procedure for acetaminophen synthesis. Catal Commun 54:11–16

Zhang JS, Riaud WAK et al (2014) Beckmann rearrangement of cyclohexanone oxime to ε-caprolactam in a modified catalytic system of trifluoroacetic acid. Catal Lett 144:151–157

Zhang JS, Lu YC, Wang AK et al (2013) Novel one-step synthesis process from cyclohexanone to caprolactam in trifluoroacetic acid. Ind Eng Chem Res 52:6377–6381

Rancan E, Quartarone G, Ronchin L et al (2015) Acid catalyzed direct-amidation–dehydrocyclization of 2-hydroxy-acetophenones to benzoxazoles by a one-pot sustainable synthesis. Catal Lett 145:939–946

Manente F, Pietrobon L, Ronchin, et al (2021) Trifluoroacetic acid hydroxylamine system as organocatalyst reagent in a one-pot salt free process for the synthesis of caprolactam and amides of industrial interest. Catal Lett 151:3543–3549

Alexandratos SD (2009) Ion-exchange resins: a retrospective from industrial and engineering chemistry research. Ind Eng Chem Res 48:388–398

Harmer M, Sun Q (2001) Solid acid catalysis using ion-exchange resins. Appl Catal A: General 221:45–62

Ronchin L, Vavasori A, Toniolo L (2012) Acid catalyzed alkylation of phenols with cyclohexene: comparison between homogeneous and heterogeneous catalysis, influence of cyclohexyl phenyl ether equilibrium and of the substituent on reaction rate and selectivity. J Mol Catal A: Chem 355:134–141

Bianchini E, Pietrobon L, Ronchin L et al (2019) Trifluoroacetic acid promoted hydration of styrene catalyzed by sulfonic resins: comparison of the reactivity of styrene, n-hexene and cyclohexene. Appl Catal A: Gen 570:130

Funding

Funding was provided by Ca' Foscari University of Venice ADIR 2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have an influence on the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cazzador, G., Manzato, L., Ronchin, L. et al. A New Sustainable Multistep Catalytic Process from Benzene to Caprolactam: Amination, Hydroximation and Beckmann Rearrangement Promoted and Catalyzed by Trifluoroacetic Acid. Catal Lett 153, 2763–2774 (2023). https://doi.org/10.1007/s10562-022-04207-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04207-9