Preliminary Study on Mini-Modus Device Equipped with a Bioreactor to Purify and Oxygenate a Synthetic Effluent

Abstract

:1. Introduction

2. Materials and Methods

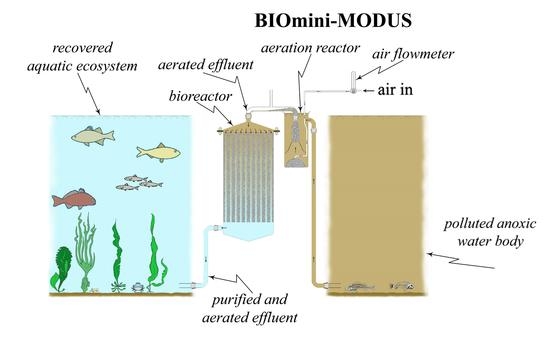

2.1. Apparatus Overview

2.2. Equipment Description

2.3. Aeration Reactor (Air-Lift)

2.4. Bioreactor

2.5. Analytical Techniques and Equipment

2.6. Biofilm Formation

2.7. Experimental Conditions

2.8. Biofilm Biomass Measurement

2.9. Respirometric Tests

2.10. Organic Matter Measurements

n CO2 + [(m − k − 3j − 2i − 3h)/2] H2O + k HX + j NH3 + i H2SO4 + h H3PO4

2.11. Synthetic Effluent Composition

2.12. Sample Filtration and Checking the Absence of Biological Activity Outside the Bioreactor

2.13. Calculation of the Energy Consumption and the Apparatus Efficiency

3. Results and Discussion

3.1. Biodegradation Experiments

3.2. Initial Dissolved Oxygen, Biodegradation Time, and Air Pressure as a Function of the Air Flow

3.3. Power, Total Energy, and Efficiency as a Function of the Air Flow

3.4. Dissolved Oxygen Concentration and BOD during a Selected Biodegradation Experiment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Perin, G.; Romagnoli, F.; Perin, F.; Giacometti, A. Preliminary study on mini-Modus device designed to oxygenate bottom anoxic waters without perturbing polluted Sediments. Environments 2020, 7, 23. [Google Scholar] [CrossRef] [Green Version]

- Soltero, R.A.; Sexton, L.M.; Ashley, K.I.; McKee, K.O. Partial and full lift hypolimnetic aeration of medical Lake, WA to improve water quality. Water Res. 1994, 28, 2297–2308. [Google Scholar] [CrossRef]

- Dai, C.; Guo, J.; Liu, J.; Donga, L.; Liu, H. Experimental Study on Aeration Performance and Bubble Characteristics of Inverted Umbrella Aerator. Water 2020, 12, 2809. [Google Scholar] [CrossRef]

- Bekassy–Molnar, E.; Majeed, J.G.; Vatai, G. Overall volumetric oxygen transfer coefficient and optimalgeometry of airlift tube reactor. Chem. Eng. J. 1997, 68, 29–33. [Google Scholar] [CrossRef]

- Dudley, J. Mass transfer in bubble columns: A comparison of correlations. Water Res. 1995, 29, 1129–1138. [Google Scholar] [CrossRef]

- Najm, I.; Trussell, R.R. New and emerging drinking water treatment technologies. In Identifying Future Drinking Water Contaminants; National academic press: Washington, DC, USA, 2021. [Google Scholar]

- Parkhill, K.L.; Gulliver, J.S. Indirect measurement of oxygen solubility. Water Res. 1997, 31, 2564–2572. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L. Wastewater Engineering: Treatment, Disposal, and Reuse, 3rd ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Spanjers, H. Respirometry in Activated Sludge. Doctoral Thesis, University of Wageningen, Wageningen, The Netherlands, 1993. [Google Scholar]

- Spanjers, H.; Vanrolleghem, P.A. Respirometry. In Experimental Methods in Wastewater Treatment; van Loosdrecht, M.C.M., Nielsen, P.H., Lopez-Vazquez, C.M., Brdjanovic, D., Eds.; IWA Publishing: London, UK, 2016. [Google Scholar]

- Perry, R.H.; Green, D.W.; Maloney, J.O. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill: New York, NY, USA, 1997. [Google Scholar]

- University of Cape Town; City Council of Jahannesburg; National Institute for water research of the Council for Scientific and Industrial Research (CSIR). Theory, Design and Operation of Nutrient Removal Activated Sludge Processes; Collaborative information for Water Research Commission; Water Research Commission: Pretoria, South Africa, 1984. [Google Scholar]

- APHA American Public Health Association. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1985. [Google Scholar]

- De Laat, J.; Wentao, W.; Freyfer, D.A.; Dossier-Berne, F. Concentration levels of urea in swimming pool water andreactivity of chlorine with urea. Water Res. 2011, 45, 1139–1146. [Google Scholar] [CrossRef] [PubMed]

- Shimadzu. Application Handbook. Sum Parameter; Shimadzu Europa GmbH: Duisburg, Germany, 2015. [Google Scholar]

- Norris, D.P.; Parker, D.S.; Daniels, M.L.; Owens, E.L. High-Quality Trickling Filter Effluent without Tertiary Treatment. J. (Water Pollut. Control. Fed.) 1982, 54, 1087–1098. [Google Scholar]

- Shimadzu Application News. TN Measurement of Urea Solution; Shimadzu Europa GmbH: Duisburg, Germany, 2018. [Google Scholar]

- Walker, K.R.; Stojowski, L.; Clifford, R.H. Total Nitrogen Analysis: ANew Perspective on TOC. 2013. Available online: http://bcodata.whoi.edu/LaurentianGreatLakes_Chemistry/totalnit.pdf (accessed on 18 August 2022).

- Baker, J.R.; Milke, M.W.; Mihelcic, J.R. Realationship between chemical and theoretical oxygen demand for specific classes of organic chemicals. Water Res. 1999, 33, 327–334. [Google Scholar] [CrossRef]

- Masotti, L. Depurazione delle Acque. Tecniche ed Impianti per il Trattamento delle Acque di Rifiuto; Calderini: Bologna, Italy, 1991. (In Italian) [Google Scholar]

- Vismara, R. Depurazione Biologica: Teoria e Processi; Hoeply: Milan, Italy, 2002. (In Italian) [Google Scholar]

- Cescon, A.; Jiang, J.-Q. Filtration process and alternative filter media material in water treatment. Water 2020, 12, 3377. [Google Scholar] [CrossRef]

- Gunam, I.B.W.; Arnata, I.W. Combination of filter media to reduce total suspended solids, biochemical, and chemical oxygen demand in wastewater using installation of horizontal roughing filter. Asian J. Microbiol. Biotechnol. Environ. Sci. 2016, 18, 867–873. [Google Scholar]

- Fitzhenry, K.; Barrett, M.; O’Flaherty, V.; Dore, W.; Cormican, M.; Rowan, N.; Clifford, E. The Effect of Wastewater Treatment Processes, in Particular Ultraviolet Light Treatment, on Pathogenic Virus Removal; EPA Research Programme 2014–2020; Environmental Protection Agency: Galway, Ireland, 2016; Available online: www.epa.ie (accessed on 5 September 2022).

- Turtoi, M. Ultraviolet light potential for wastewater disinfection. Ann. Food Sci. Technol. 2013, 14, 153–164. [Google Scholar]

- USACHPPM. Ultraviolet Light Disinfection in the Use of Individual Water Purification Devices, IWP Individual Water Purifer, Pathogen Removal, Potable Water. 2006. Unclassified Document 31-006-0306. Available online: http://handle.dtic.mil/100.2/AD453967 (accessed on 27 June 2022).

- Azami, H.; Sarrafzadeh, H.M.; Mehrnia, R. Soluble microbial products (SMPs) release in activated sludge systems: A review. Iran. J. Environ. Health Sci. Eng. 2012, 9, 30. [Google Scholar] [CrossRef] [PubMed]

- Burzio, C. Soluble Microbial Products (SMP) and Bacteriophages in Activated Sludge. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Barker, D.J.; Stukey, D.C. A review of soluble microbial products (SPM) in wastewater treatment systems. Water Res. 1999, 33, 3063–3082. [Google Scholar] [CrossRef]

- Bekins, B.A.; Godsy, E.M.; Warren, E. Comparison of Zero-Order, First Order, and Monod Biotransformation Models. Ground Water 1998, 36, 261–268. [Google Scholar] [CrossRef]

- Loyless, J.C.; Malone, R.F. Evaluation of the air-lift pump capabilities for water delivery, aeration, and degasification for application to recirculating aquaculture systems. Aquacult. Eng. 1998, 18, 117–133. [Google Scholar] [CrossRef]

- Fondriest, Environmental Learning Center. Dissolved Oxygen, Environmental Measurement Systems. 2013. Available online: https://www.fondriest.com/environmental-measurements/parameters/water-quality/dissolved-oxygen/ (accessed on 20 July 2022).

- Webb, P. Temperature–Introduction to Oceanography. Roger Williams University. 2021. Available online: https://rwu.pressbooks.pub/webboceanography/chapter/6-2-temperature/ (accessed on 30 September 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perin, G.; Romagnoli, F.; Perin, F.; Bonardi, M.; Romano, F.; Floretta, C.; Giacometti, A. Preliminary Study on Mini-Modus Device Equipped with a Bioreactor to Purify and Oxygenate a Synthetic Effluent. Environments 2023, 10, 21. https://doi.org/10.3390/environments10020021

Perin G, Romagnoli F, Perin F, Bonardi M, Romano F, Floretta C, Giacometti A. Preliminary Study on Mini-Modus Device Equipped with a Bioreactor to Purify and Oxygenate a Synthetic Effluent. Environments. 2023; 10(2):21. https://doi.org/10.3390/environments10020021

Chicago/Turabian StylePerin, Guido, Francesco Romagnoli, Fabrizio Perin, Maurizio Bonardi, Franco Romano, Caterina Floretta, and Andrea Giacometti. 2023. "Preliminary Study on Mini-Modus Device Equipped with a Bioreactor to Purify and Oxygenate a Synthetic Effluent" Environments 10, no. 2: 21. https://doi.org/10.3390/environments10020021